Stud bolts are used in construction, mechanical system and industrial piping. It has an important role in holding heavy parts together. They are known for strength, simple design and easy to use.

Studs do not have head they are threaded on both ends and are often used with two nuts to make secure connections. Because of this they are often found in places where high pressure, temperature, or vibration exists. This includes oil and gas plants, power stations, shipyards, and heavy machinery.

Understanding the different types of stud bolts is important when selecting the right one for the job. Each type has a different purpose like thread size, length, material and application will determine the best choice. Below are the main type of stud bolts and their uses

-

Fully Threaded Stud Bolts

Fully threaded stud bolts have threads along the entire length of the bolt. These are among the most common types. They provide a firm and uniform grip when used with nuts. These studs are easy to install and remove. They are used where both ends of the bolt are accessible and a strong clamp is needed.

Uses:

- Flange joints in pipelines

- Heat exchangers

- Pressure vessels

- Boilers

- Structural applications in steel buildings

Tap End Stud Bolts

Tap end studs have threads at both ends, but the threads are not equal. One end has a short thread which is screwed into a tapped hole, while the other end is longer and takes a nut. These bolts are mostly used when one side of the joint has a blind hole.

Uses:

- Engine blocks

- Pumps

- Compressors

- Turbines

- Equipment mounting systems

Double End Stud Bolts

Double end studs have equal thread lengths on both ends with an unthreaded section in the middle. The center part helps with alignment and adds strength to the bolt. These bolts are often used when parts must be held in exact position.

Uses:

- Heavy machinery

- Structural joints

- Automotive engines

- Mounting brackets

Continuous Thread Stud Bolts

These are very similar to fully threaded bolts but are mainly used in lower pressure or low-stress conditions. They are simple and affordable. These bolts allow for easy adjustment or replacement and are often used in simple fastening systems.

Uses:

- Furniture joints

- Light structural work

- Frame assembly

- Cabinet fittings

Reduced Shank Stud Bolts

These bolts have a thinner centre section between the threads. The reduced diameter helps reduce stress and weight. It also allows for better flexibility and heat expansion. This design helps prevent fatigue failure over time.

Uses:

- Aircraft engines

- Marine turbines

- Power generation systems

- Vibrating machinery

Flange Stud Bolts Flange

Stud bolts are used to connect flanges in piping systems. These bolts are designed to provide a tight seal and withstand high pressure and temperature. They are often paired with gaskets to ensure leak-free operation.

Uses:

- Oil and gas pipelines

- Petrochemical plants

- Water treatment systems

- Offshore drilling rigs

- Chemical processing

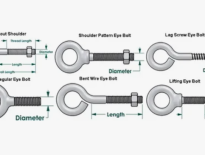

Stud Bolts with Shoulder

These bolts include a shoulder or unthreaded stop in the middle of the stud. This feature allows precise placement of the stud bolt in the joint. The shoulder stops the bolt from going deeper and provides better alignment.

Uses:

- Gearbox housings

- Valve bodies

- High-precision equipment

- Engines and transmissions

Welded Stud Bolts

Welded studs have one end welded directly to the base metal. The other end is threaded to accept a nut. These bolts are often used in applications where only one side is accessible or where the stud needs to stay in place permanently.

Uses:

- Shipbuilding

- Heavy steel structures

- Pipe supports

- Mounting panels

Double-End Stud Bolts with Unequal Thread Lengths.

These bolts are similar to regular double-end studs but with uneven threads on both ends. One side is shorter, and the other longer. This setup is used in special applications where different nut sizes or load conditions exist on each side.

Uses:

- Complex machinery

- Heavy-duty engines

- Special flange connections

Partial Thread Stud Bolts

These bolts have threads only at both ends, and a plain section in the middle. The plain part gives strength and helps with load distribution. This type is common where bolts are subject to heavy shear forces.

Uses:

- Mechanical couplings

- Machine joints

- Rotating parts

Materials Used in Stud Bolts

Stud bolts are made using a variety of materials depending on their end-use. The most common materials include:

- Carbon Steel: Used in general-purpose bolts. It is strong and low-cost.

- Stainless Steel: Offers corrosion resistance. Good for marine and chemical uses.

- Alloy Steel: Used in high-strength applications. It can withstand high pressure and heat.

- Brass or Bronze: Used in non-sparking environments. Also resistant to corrosion.

- Inconel, Monel, Hastelloy: High-performance alloys used in extreme environments like offshore drilling and chemical plants.

Coatings and Surface Treatments

To improve life and performance, stud bolts often come with special coatings:

- Zinc Plating: Prevents rust. Suitable for dry environments.

- Hot-Dip Galvanizing: Offers strong protection for outdoor or moist conditions.

- Teflon Coating: Reduces friction and adds chemical resistance.

- Black Oxide: Provides mild corrosion resistance.

Applications Across Industries

Stud bolts are used across many industries because they are strong and easy to work with. Below are a few key areas where they are common:

- Oil and Gas Industry

This sector uses a large number of stud bolts. These bolts are used to connect pipes, flanges, valves, and pressure vessels. The harsh environment requires strong materials and good sealing.

- Power Plants

Stud bolts are used in boilers, turbines, and heat exchangers. These settings demand bolts that can handle both high heat and pressure.

- Petrochemical

Plants Chemical exposure is common here. Stud bolts must resist corrosion while also offering strong hold.

- Shipbuilding and Marine

Stud bolts used here must resist saltwater and rust. Stainless steel or copper alloys are often used.

- Construction

In structural work, stud bolts hold steel frames and joints. They are easy to replace or tighten.

- Automotive and Engines

Stud bolts are used in engine blocks, transmissions, and other parts that need strong and stable connections.

- Heavy Equipment and Machinery

Stud bolts secure large parts that are hard to move. Their design makes it easier to fix worn-out parts without disturbing the whole setup.

- Aerospace Industry

Lightweight and strong bolts like titanium or alloy steel studs are used here. These bolts can handle vibration and stress well.

Benefits of Using Stud Bolts

- High Strength: They can handle heavy loads, pressure, and heat.

- Easy to Maintain: Stud bolts can be removed and replaced without removing other parts.

- Good Alignment: Offers better balance and helps in exact positioning.

- Cost-effective: Lower downtime and easier maintenance make them budget-friendly in the long run.

Custom Sizes: They can be made in any size, length, or thread pattern as per need.

How to Choose the Right Stud Bolt

When choosing a stud bolt, consider the following:

- Application Type: Is it for high pressure, temperature, or vibration?

- Material Match: Will it resist corrosion or heat?

- Size and Thread: Match bolt size to nut and hole.

- Load Needs: Can it handle the weight and stress?

- Industry Standard: Use bolts that meet ASTM, DIN, or ISO standards.

Conclusion

Stud bolts are simple yet powerful tools used in almost every industry. They help join parts firmly and offer safety, durability, and easy upkeep. With many types to choose from, each has a specific use. Picking the right type and material will ensure long-term performance and safety.

From oil rigs to engines, stud bolts play a key role in keeping systems running smoothly. Knowing their types and uses will help you make smart choices in any project.