Bolts are employed in nearly all industries where there is a requirement for strong and dependable joints. From manufacturing to building they assist in joining various parts and stabilizing structures. Not all bolts are created equally, however. The type of bolt selected can have implications on performance as well as safety. Two of the most popular types stud bolts and hex bolts are utilized for different applications and are suited for different scenarios. This guide describes what makes them unique, how they are applied and why one might be more suitable than the other.

What Are Stud Bolts?

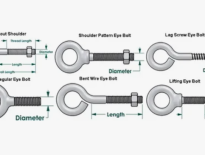

Stud bolts are threaded rods without a head. They usually come in fully threaded or double-end versions. In fully threaded types, the entire length has threads. In tap-end or double-end types, threads are only at both ends. They are intended to be utilized with nuts on each side to have strong clamping force. The bolts are constructed with carbon steel, alloy steel, or stainless steel and usually coated for corrosion protection. Coatings used are zinc plating, PTFE, or galvanization. The stud bolts can be found on most high-pressure and high-temperature systems such as pipelines, heat exchangers, and flanged joints. Their headless construction finds them well-suited for locations where space is at a premium and there are two sides of access.

What Are Hex Bolts?

Hex bolts have a six-sided head and a partially or fully threaded shank. They are secured with a wrench or socket. Hex bolts are among the most popular fasteners used in industries. Hex bolts come in various grades and are usually constructed using stainless steel, carbon steel, or alloy steel. They can also be surface-treated with coatings such as black oxide, hot-dip galvanizing or zinc plating. Hex bolts are widely used in construction, machinery, automotive, and structural applications. Being easy to install and readily available, they are a first-choice solution for general applications where there is no need to operate under extreme conditions.

Key Differences Between Stud Bolts and Hex Bolts

Design and Structure

Stud bolts don’t have a head. They are straight rods with threads on both ends or all over. Hex bolts have a built-in hexagonal head for tightening. Stud bolts are used with two nuts, while hex bolts are used with a nut and turned with a tool.

Installation Method

Stud bolts need access to both ends. They’re installed by securing nuts on either side. Hex bolts can be tightened from one end using a wrench or a socket. This makes hex bolts easier to install in tight or one-sided spaces.

Load Distribution and Strength

Stud bolts provide even load distribution across both nuts. They hold up well under high pressure and temperature. Hex bolts are strong but may not be ideal in extreme environments. Stud bolts are better at handling vibrations and sealing joints tightly.

Maintenance and Replacement

Stud bolts are easier to remove and replace without disturbing the entire setup. This is useful in maintenance-heavy systems. Hex bolts are simple to replace but may require full access and disassembly of the joint.

Applications and Suitability

Stud Bolts are commonly used in environments that demand high performance under pressure and temperature. They are a preferred choice in industries like oil and gas, power generation, petrochemicals, and shipbuilding. One of their most important applications is in flanged connections—where consistent tension and reliable sealing are essential. Stud bolts allow for a strong, secure grip between two flanges, even in systems with intense pressure or thermal expansion. Their headless design also makes them suitable for equipment that needs frequent inspection or maintenance, as they can be removed and replaced without disturbing the surrounding components.

Hex Bolts, on the other hand, are more suitable for general-purpose fastening. They are widely used in construction, automotive parts, machinery, and furniture assembly. Their ease of installation, availability in various sizes, and cost-efficiency make them a go-to fastener for day-to-day structural needs. Hex bolts work best where space isn’t a constraint and where the operating conditions are stable, without extreme heat, pressure, or vibration. They’re ideal for assembling frames, equipment housings, brackets, and other non-critical components.

Pros and Cons

Stud Bolts

Pros:

- High Strength: Built to withstand high loads, making them suitable for critical industrial applications.

- Excellent Clamping Force: The use of two nuts offers balanced pressure on both sides, ensuring a firm grip.

- Ideal for Confined Spaces: Their headless design allows installation in areas with limited clearance.

Cons:

- Requires Nuts on Both Sides: Needs access from both ends, which can be difficult in tight or one-sided assemblies.

- More Components to Handle: Additional nuts and washers mean more parts, which can increase installation time.

Hex Bolts

Pros:

- Easy to Install: Can be fastened with a wrench or socket from one side, simplifying the process.

- Widely Available: Common across industries and readily available in most hardware and supply stores.

- Cost-Effective: Fewer parts and easier installation help reduce labor and material costs.

Cons:

- Not Ideal for Extreme Conditions: May not hold up as well in high-pressure or high-temperature environments.

- Can Loosen Under Vibration: In dynamic or vibrating systems, they may require extra locking solutions.

How to Choose the Right Fastener for Your Project

The right bolt depends on what you’re building and the conditions it will face. For high-pressure joints or tight spaces, stud bolts are a better fit. For standard construction and machinery, hex bolts are often enough. Consider the load, temperature, vibration, and ease of maintenance when deciding. Always use quality-tested fasteners that meet industry standards.

Conclusion

Stud bolts and hex bolts each have their place in engineering and construction. Stud bolts offer greater strength and sealing, while hex bolts are simple and versatile. Knowing when to use each type can save time, reduce risk, and improve performance. Choose the one that fits the job based on design, environment, and durability.